Features And Benefits Of HZS120 Concrete Mixing Plant:

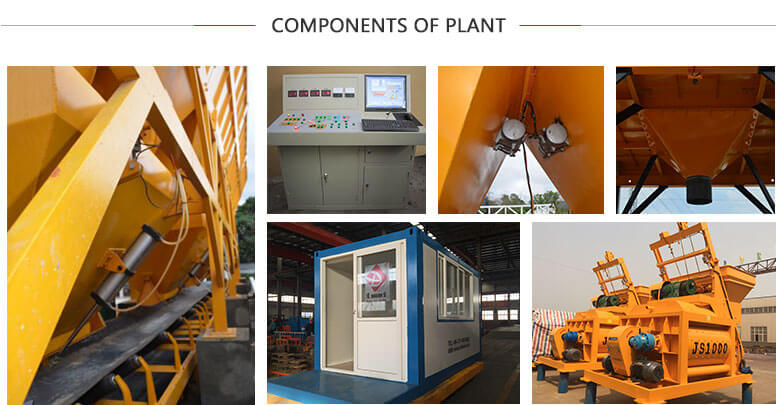

Mixing system choose twin-shaft forced concrete mixer, which has high efficiency and good mixing quality, scale board and mixing blades adopts high-rigidity and high tenacity wearable alloy steel, to prolong the working life.

Scale components of measurement system are all from famous brand, computer controlled to ensure the weighing accurate and reliable performance, so that it can also meet the requirement of every high performance good concrete.

Aggregate feeding system adopts Belt Conveyor, can be assembled rainproof and tighten device for belt. Aggregate lifting appliance adopts frequency control, thus providing smooth and reliable operation.

Lubrication system adopts advanced centralized oil lubricating system, convenient for oil supplying, this system is equipped with overvoltage warning and low oil level warning, safe and reliable.

Control system ensures the high simple and reliability, human-based intelligent control facilitates the continuously producing, but with dynamic display panel to make the operator clearly know the operation of each part.

Assemble sidewalk and ladders for every maintenance and service part, assemble high-pressure water flushing device for concrete mixer clean, good maintainability.

All of powder material is feeding, batching, unloading, mixing in closed space., reduce the pollution to environment. Assemble dust-remover in main mixing building, and also pack the mixing building and belt conveyor.

Working Principle Of HZS120 Ready Mix Concrete Plant:

Turn on control software, login to operation interface;

Set or access working parameters of concrete production, such as recipe number, concrete grade, slump, total production volume, etc.

The software/PLC will give signal to each part of the plant, to finish the material feeding, measurement, loading into the concrete mixer, mixing and discharging;

If there are some problems during production, the software will detect the error and light up alarm lamp on computer screen or indicator display, so that the operator can stop the production till problems solved.

Regarding to the material feeding, the various of electric motors, butterfly valves and load cells will work automatically according to digital signal;

High-pressure air system will provide enough driving force for each unloading gates, such as aggregate bins, butterfly valve of scale hoppers, concrete mixer discharging gate, etc.

The software will control the whole system continuously produce concrete till the set-volume finished production, unless emergency stop or turn to Manual style.

Shipment of DASION Concrete Batching Plants:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)